BioVeritas, a company from the United States, is a success story and example of what upcycling can do for us to achieve sustainable development and for those who want to undertake and be successful with it.

BioVeritas knew how to use by-products and underutilized products from the food industry, such as leftover wheat used to produce pasta, for example, to transform them into organic acids and use these acids in precision fermentation. It seems complicated, but it’s not. Let’s explain it better.

Precision fermentation

We’ve already said everything about precision fermentation here, but just for explanation purposes, let’s give a brief summary. This type of fermentation is nothing more than a process that uses yeast or bacteria, genetically modifies them and uses them to produce specific proteins or fats.

This is the famous case of producing milk without needing a cow. And it was in this process that BioVeritas invested.

The company’s precision fermentation tanks./ Image: BioVeritas

Success story

The company’s focus is not on producing other foods from underutilized foods in the industry, but rather on manufacturing products that help producers obtain better results from their merchandise.

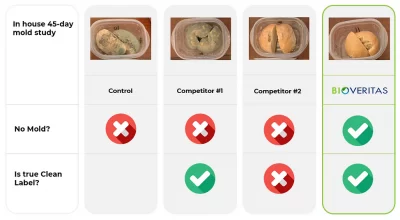

For example, one of BioVeritas’ upcycling creations was a mold inhibitor for baked goods.

Demonstration of how BioVeritas’ mold inhibitor is effective against mold in bread./ Image: BioVeritas

In this way, the concern with sustainability is found at both ends. First, BioVeritas takes wasted food, then manufactures a product that can extend the shelf life of food even further, in other words, reducing food waste further.

The company also manufactures products that are typically petrochemicals, such as ammonia, through precision fermentation. This makes the process cleaner and beneficial for both the environment and the consumer.

The mold inhibitor we mentioned above, for example, is made from propionic acid, a compound found naturally in materials such as wood.

Other products manufactured by BioVeritas are postbiotics, frequently used for lubricating aircraft and in the production of cosmetics. To manufacture these products, the majority of the raw materials used by the company are food waste, such as: alfalfa, sugar cane pulp, pineapple and orange peels and seeds.

Alfafa

Reaping the fruits

Due to this innovative proposal, BioVeritas received an investment of 65 million dollars in 2022 to continue expanding its manufacturing of upcycled products.

Furthermore, the company has plans and projections to build a new facility that will allow it to produce on a commercial scale. As a result, it is estimated that profits could reach almost 50 million pounds per year from 2025 onwards. In other words, the company is becoming a true success story.

So, what we can conclude is that upcycling is becoming not just a path to sustainability, but a business. And, even better, a profitable business.

How about you also invest in upcycling? Count on Upcycling Solutions for that!

Sources: Food Dive, Bakery and Snacks, Unconventional Ag

COMMENTS